Show Me The Packages

Maximize Your Porsche 911 Ride Quality

Suspension technology and materials have improved significantly over the decades and your classic Porsche can handle better than it did when it left Stuttgart when fitted with today’s bushings and components.

We offer replacement parts direct from Porsche as well as our own Elephant Racing brand of suspension components that will eliminate squeeks, groans, increased fuel consumption, and road-wandering qualities of worn bits.

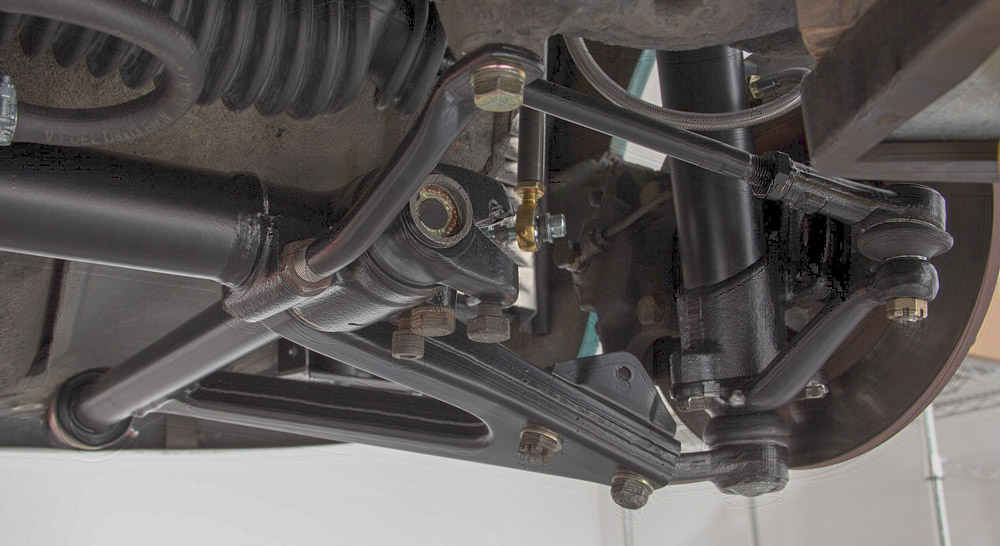

With new bushings, ball joints, tie rod ends, shocks & mounts, and properly adjusted suspension components your car will drive straight down the road quietly with less driver fatique and better fuel economy.

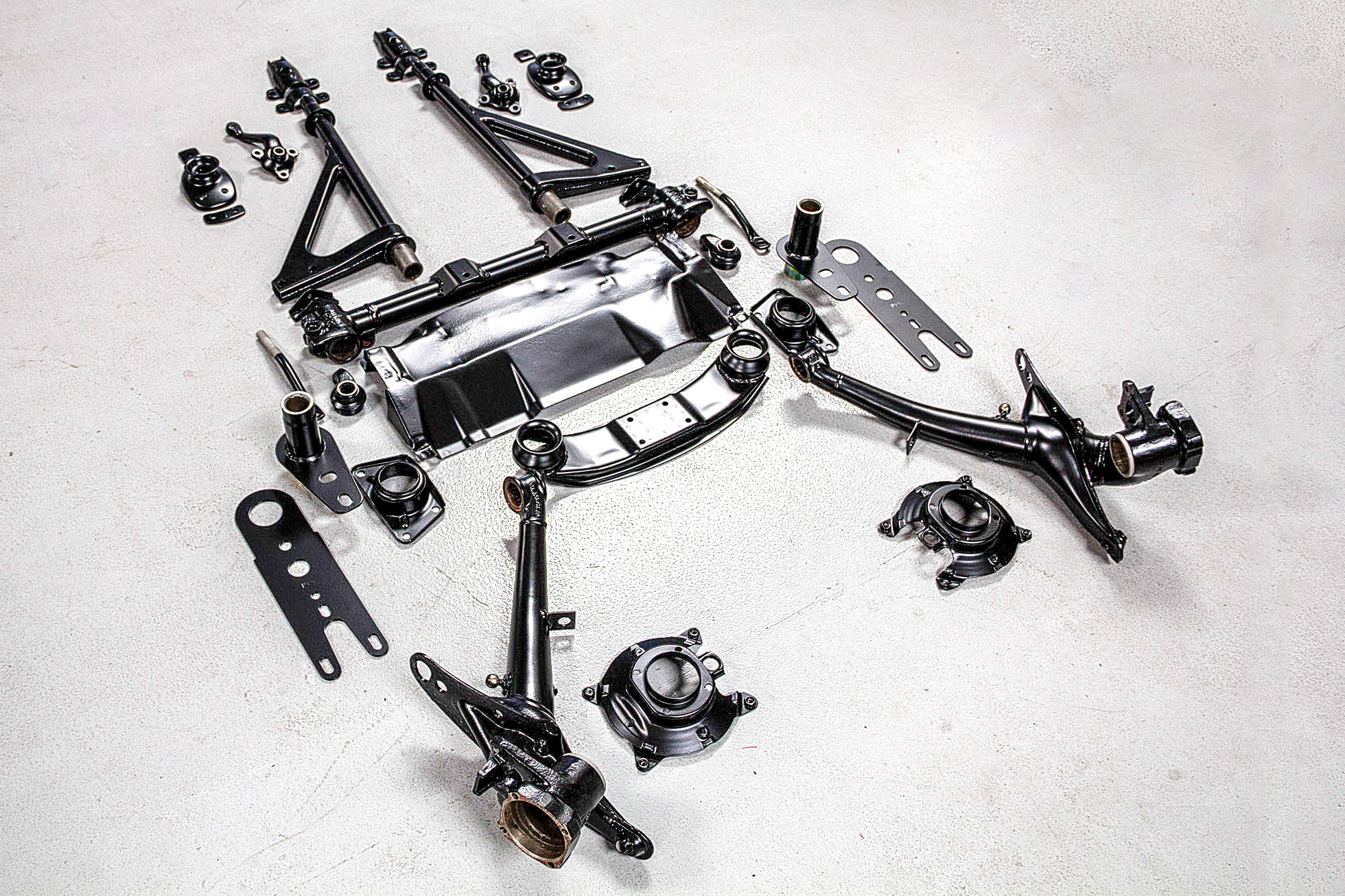

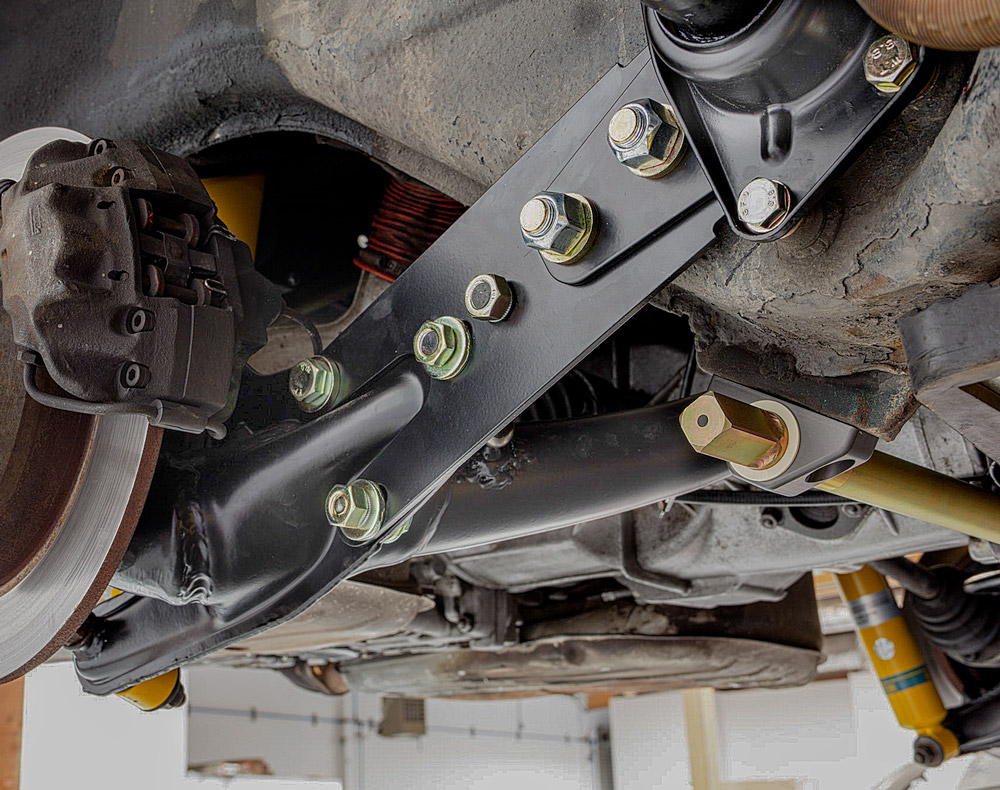

If you have a full vehicle restoration on your agenda we can take your control arms, trailing arms, spring plates, etc… and completely refurbish them before shipping back to you. Depending on the component and year of your car we will disassemble, sandblast, powdercoat/zinc plate/paint, and reassemble with all new bearings and components. You will recieve your original components rebuilt and ready to install. You can see all our services here or call us at 408-297-2789.

Trailing Arm Rubber Bushing Replacement

Spring Plate Rubber Bushing Removal

Control Arm Rubber Bushing Comparison

Control Arm Rubber Bushing Replacement Overview

Restoring Confidence

A New Lease on Life

Eventually every car arrives at a crossroad where an owner has to decide whether it makes more sense to part ways with an old friend or to renew an enduring bond. With other makes and models, especially those serving duty as mere transportation conveyances, this often comes down to a simple ROI calculation looking at whether it’s more cost effective to move on to a newer model or to service and maintain an existing car.

Eventually every car arrives at a crossroad where an owner has to decide whether it makes more sense to part ways with an old friend or to renew an enduring bond. With other makes and models, especially those serving duty as mere transportation conveyances, this often comes down to a simple ROI calculation looking at whether it’s more cost effective to move on to a newer model or to service and maintain an existing car.

And then there are classic Porsches…

- “I just returned from driving my ’87 911 to the Porsche Parade in Savannah and I wanted to let you know it drove great. Over 2500 miles and it drove rock solid…. Your suspension products made the world of difference to the car’s overall ride.”Leo L., Texas, US – Suspension Updates

- “My order was beyond expectations. Great packaging to avoid damage and your products are first class!”Jeff A. – 911

Suspension Tech

Reinforcement

Safari cars are great fun just driving down the street. But a whole new dimension happens off road. Rugged terrain loads the suspension and chassis in ways that street cars never see. Robust as is, the 911 chassis has known vulnerabilities. Any serious safari build should address these proactively, before they fail.

Safari cars are great fun just driving down the street. But a whole new dimension happens off road. Rugged terrain loads the suspension and chassis in ways that street cars never see. Robust as is, the 911 chassis has known vulnerabilities. Any serious safari build should address these proactively, before they fail.

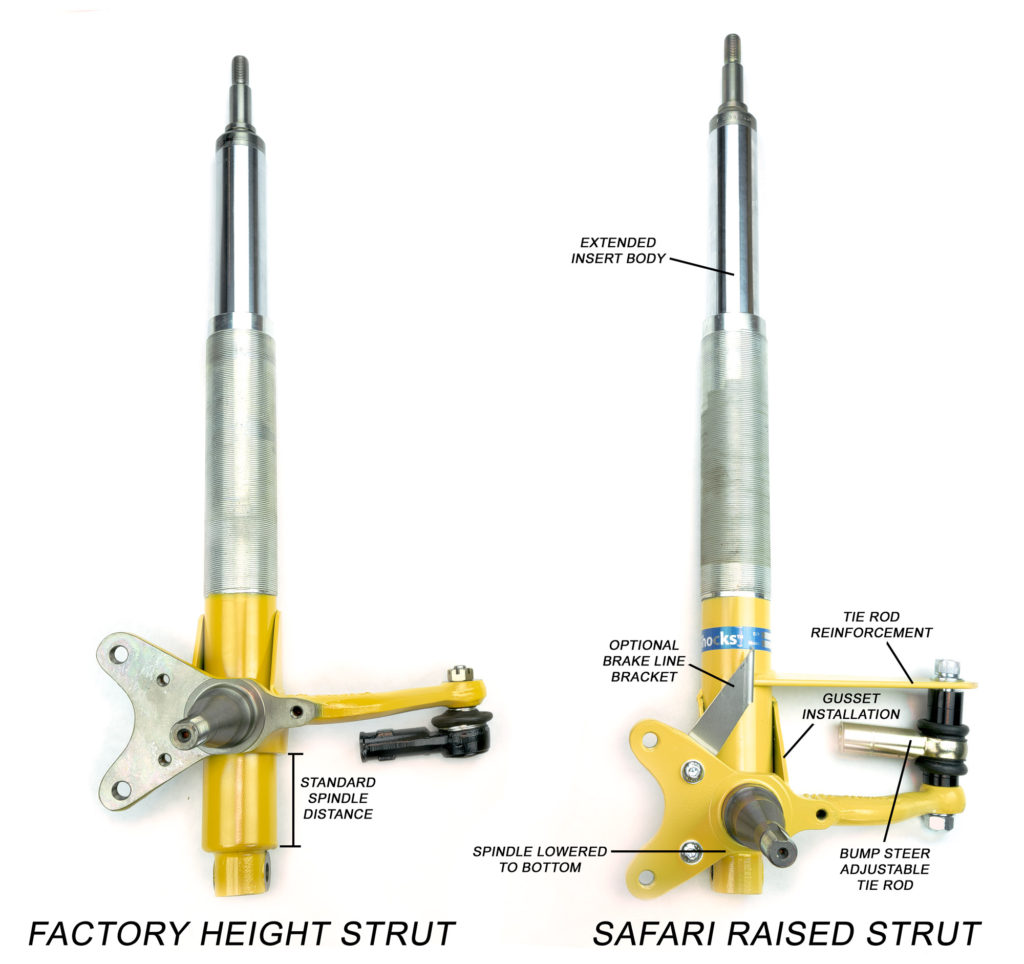

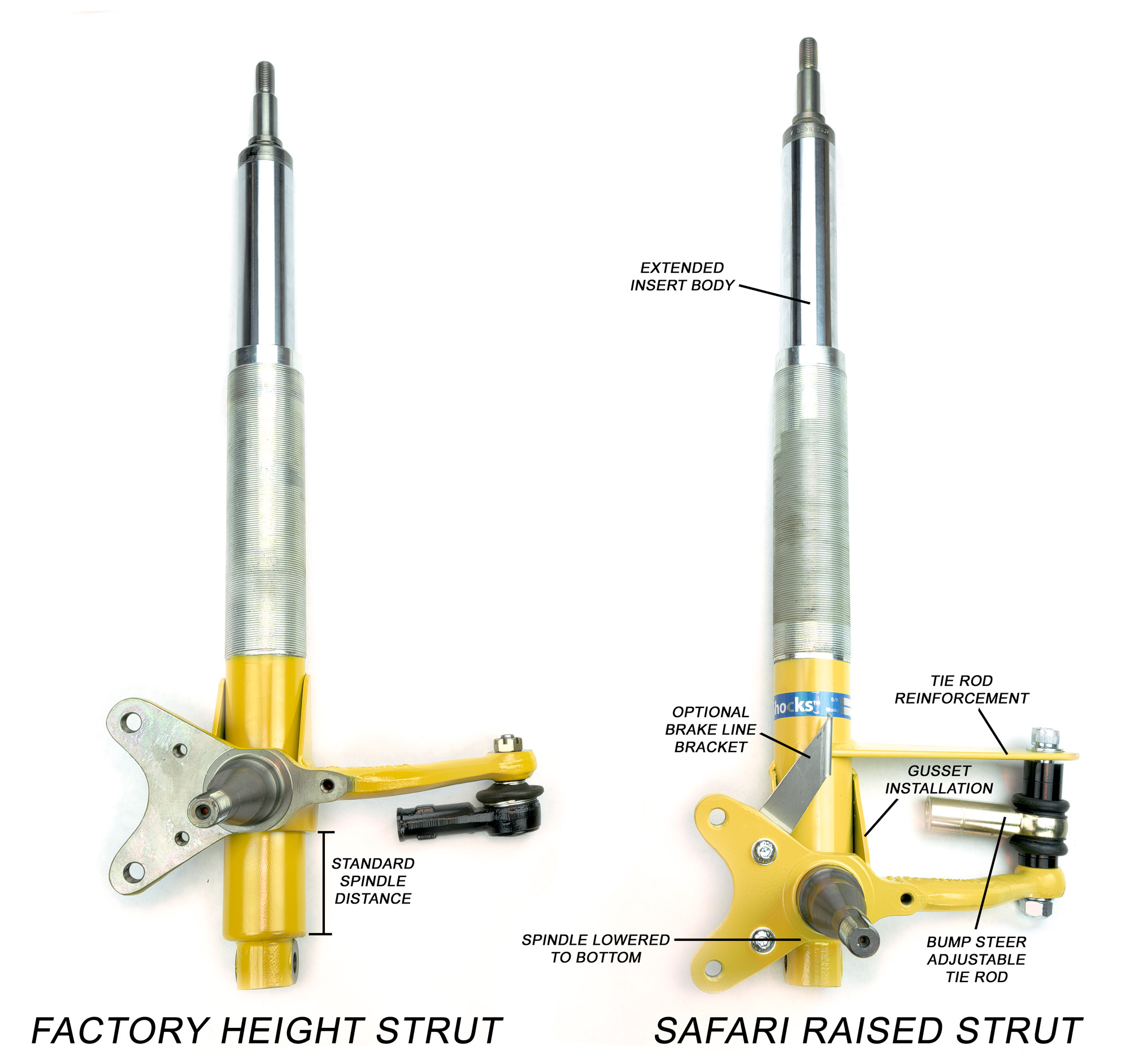

Suspension Travel and Geometry

Unlike most cars, 911s have adjustable ride height right from the factory. Does that mean you can just raise your stock suspension to achieve the safari height you covet? No, it does not.If you simply raise the ride height you are putting the suspension into droop and the angles of the suspension members change in undesirable ways. You will introduce geometry, suspension travel and alignment problems, as well as potentially create unsafe condition with parts breakage.

Unlike most cars, 911s have adjustable ride height right from the factory. Does that mean you can just raise your stock suspension to achieve the safari height you covet? No, it does not.If you simply raise the ride height you are putting the suspension into droop and the angles of the suspension members change in undesirable ways. You will introduce geometry, suspension travel and alignment problems, as well as potentially create unsafe condition with parts breakage.

Lift Height and Tire Selection

How much can you raise the car? Total height is determined by a combination of the suspension rise plus the increase due to larger tire diameter.Our safari suspension kits put the suspension into a reasonable range of adjustment 2-3 inches higher than stock. Tires typically add 0.5″-1″ (12mm-25mm) to that for a total height increase of 2.5″-4″ (62mm-100mm). A very substantial left gain.

How much can you raise the car? Total height is determined by a combination of the suspension rise plus the increase due to larger tire diameter.Our safari suspension kits put the suspension into a reasonable range of adjustment 2-3 inches higher than stock. Tires typically add 0.5″-1″ (12mm-25mm) to that for a total height increase of 2.5″-4″ (62mm-100mm). A very substantial left gain.

Coilover vs Torsion Bar

All 911s through 1989 use torsion bars as the springs from the factory. The chassis is designed to accept the suspension loads and carry the weight of the car though the torsion bars, related bushings and attachment points.

All 911s through 1989 use torsion bars as the springs from the factory. The chassis is designed to accept the suspension loads and carry the weight of the car though the torsion bars, related bushings and attachment points.

Suspension Bushings

Suspension bushing selection is critically important functions on off road vehicles. The demands and needs are very different from road cars.

Suspension bushing selection is critically important functions on off road vehicles. The demands and needs are very different from road cars.

Stiffness

How stiff should a safari suspension be? That really depends on how the car will be used.Cars that will run off-road over uneven terrain will benefit from softer suspension setups. This provides the compliance needed to allow the tires to follow and stay in contact with the surface.

How stiff should a safari suspension be? That really depends on how the car will be used.Cars that will run off-road over uneven terrain will benefit from softer suspension setups. This provides the compliance needed to allow the tires to follow and stay in contact with the surface.

Attention to Detail & Personal Service

Our Safari Suspensions need not be a permanent modification. Run your Safari setup as long as you like, but should you ever decide to revert back to factory ride height, this is very easy to do.

Our Safari Suspensions need not be a permanent modification. Run your Safari setup as long as you like, but should you ever decide to revert back to factory ride height, this is very easy to do.

SUSPENSION RESTORATION PACKAGES

Suspension Restoration Packages for Porsche 911, 912, & 930

Some Recent Customer Suspensions

Eventually every car arrives at a crossroad where an owner has to decide whether it makes more sense to part ways with an old friend or to renew an enduring bond. With other makes and models, especially those serving duty as mere transportation conveyances, this often comes down to a simple ROI calculation looking at whether it’s more cost effective to move on to a newer model or to service and maintain an existing car.

Eventually every car arrives at a crossroad where an owner has to decide whether it makes more sense to part ways with an old friend or to renew an enduring bond. With other makes and models, especially those serving duty as mere transportation conveyances, this often comes down to a simple ROI calculation looking at whether it’s more cost effective to move on to a newer model or to service and maintain an existing car.